模具被稱作工業(yè)之母,除開由于它可以使產(chǎn)品設(shè)計(jì)變?yōu)閷?shí)物外,更關(guān)鍵的是它可以提升模具加工率,降低成本費(fèi),開展大批量拷貝。但是因?yàn)樽⑺苣>叩募夹g(shù)性規(guī)定較高,因此穩(wěn)步長久的發(fā)展趨勢離不開的注塑模具制造加工工藝水準(zhǔn)。注塑模具制造加工難的緣故是什么?

Mold is known as the mother of industry. Apart from making product design into physical objects, the more important thing is that it can improve the efficiency of mold processing, reduce the cost and carry out mass copying. However, due to the high technical requirements of injection molds, the steady and long-term development trend cannot be separated from the cutting-edge injection mold manufacturing and processing technology level. What is the reason for the difficulty in manufacturing injection molds?

復(fù)雜的型腔和型芯。

Complex cavities and cores.

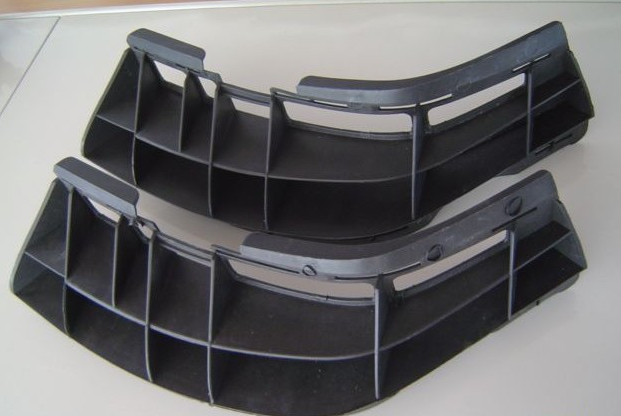

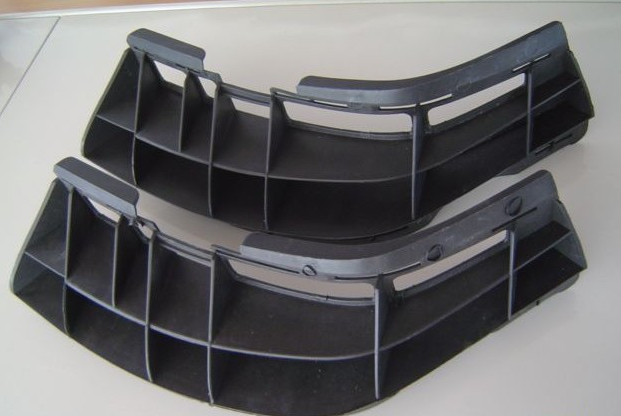

塑料件是由型腔和型芯組合而成,直接注塑成型。復(fù)雜的型腔加工難度比較大,特別是一些型腔的盲孔型內(nèi)成型面加工。在這種情況下,如果采用傳統(tǒng)的注塑模加工方式,除了會消耗較多的副工夾具、刀具,還需要有經(jīng)驗(yàn)的注塑模制造師傅,注塑模加工周期也會延長。

Plastic parts are composed of cavity and core, and are directly injection molded. It is very difficult to process complex cavities, especially the processing of blind hole and inner molding surface of some cavities. In this case, if the traditional injection mold processing method is adopted, in addition to consuming more auxiliary fixtures and tools, experienced injection mold manufacturers are also required, and the injection mold processing cycle will be prolonged.

對塑料件的精度和外觀要求高。

High precision and appearance requirements for plastic parts.

頂出裝置是影響塑料零件變形和尺寸精度的重要因素。因此,在注塑模具設(shè)計(jì)中,應(yīng)選擇頂出點(diǎn),以確保塑料零件均勻脫模。在結(jié)構(gòu)設(shè)計(jì)中,大多數(shù)高精度注塑模具采用鑲嵌或全拼接結(jié)構(gòu),大大提高了模具零件的加工精度和互換性。

Ejection device is an important factor that affects the deformation and dimensional accuracy of plastic parts. Therefore, in the design of injection mold, the ejection point should be selected to ensure that the plastic parts are evenly demoulded. In the structural design, most of the high-precision injection molds adopt inlay or full splicing structure, which greatly improves the processing accuracy and interchangeability of the mold parts.

工藝繁瑣,制造加工時間緊迫。

The process is complicated and the manufacturing time is urgent.

濟(jì)南注塑加工人員認(rèn)為大多數(shù)塑料零件都是由配套零件組成的完整產(chǎn)品,因此對精度有很高的要求。模具制造完成后,須反復(fù)測試和校正。因此,注塑模具的設(shè)計(jì)、開發(fā)和交付周期是緊迫的,每個環(huán)節(jié)都不容忽視。

Jinan injection molding processing personnel believe that most plastic parts are complete products composed of supporting parts, so they have high requirements for accuracy. After the mold is manufactured, it must be tested and corrected repeatedly. Therefore, the design, development and delivery cycle of injection mold are urgent, and each link can not be ignored.

造成注塑模具加工困難的原因大體上就是以上所講解的內(nèi)容了,如果您對注塑模具有技術(shù)問題,歡迎您登錄我們的網(wǎng)站

http://www.xjfff.com了解更多信息,讓您在使用期間順利進(jìn)行操作而不會出現(xiàn)問題。

The reason for the difficulty in processing injection molds is basically the content explained above. If you have technical problems with injection molds, please visit our website http://www.xjfff.com Learn more so that you can operate smoothly without problems during use.